As global industries race to adopt AI-driven production lines and IoT-enabled machinery, one component quietly anchors this transformation: the industrial socket box . These unassuming yet critical units are evolving from simple power hubs into intelligent nodes that bridge physical infrastructure with digital manufacturing ecosystems. With supply chains prioritizing agility and factories embracing predictive maintenance, next-generation socket boxes are redefining industrial resilience.

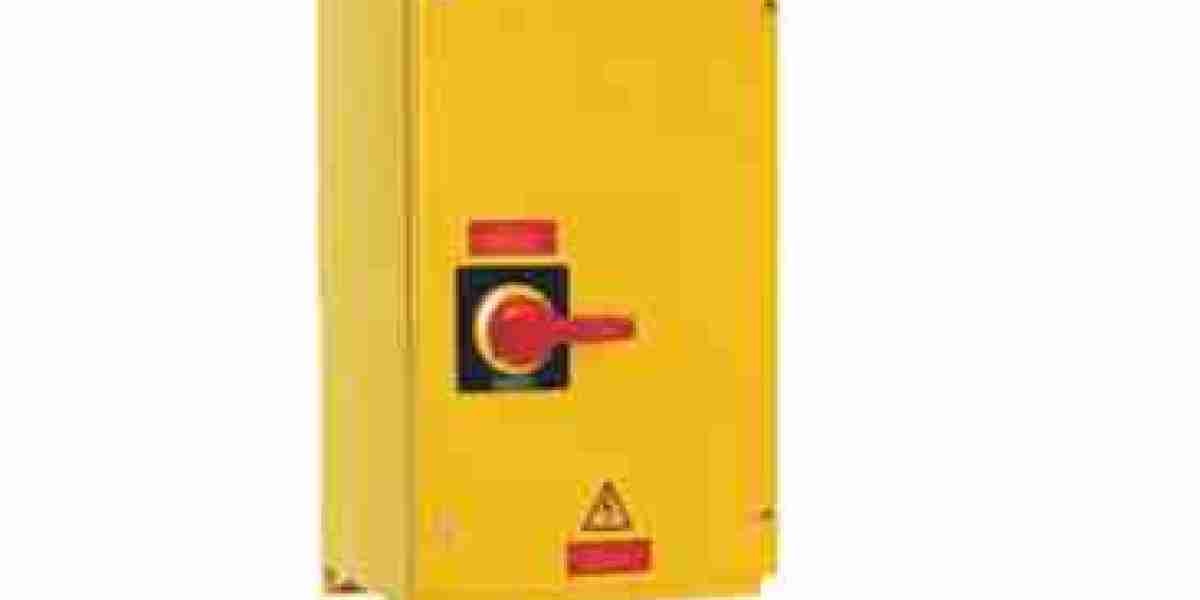

The shift toward decentralized, data-driven manufacturing demands power systems that adapt in real time. Modern industrial socket boxes now integrate modular designs, allowing factories to reconfigure energy distribution for collaborative robots, additive manufacturing tools, or autonomous logistics vehicles. Their hardened casings withstand harsh environments—from foundries to automated warehouses—while embedded sensors monitor load fluctuations, preempting equipment failures.

A key driver is the rise of "lights-out" factories, where human intervention is minimized. Here, industrial socket boxes serve as lifelines for 24/7 robotic arms and machine vision systems. Their quick-connect interfaces enable rapid redeployment of production lines, aligning with just-in-time manufacturing trends. For instance, automotive plants leverage these units to switch between EV battery assembly and traditional powertrain setups without downtime—a flexibility critical amid shifting market demands.

Sustainability also shapes their evolution. Factories now prioritize socket boxes with energy-optimized circuits that reduce idle consumption, aligning with carbon-neutral goals. The ability to upgrade individual modules—rather than replacing entire systems—minimizes e-waste, a growing concern as nations tighten regulations on industrial sustainability.

Safety remains non-negotiable. Advanced models feature self-diagnostic capabilities, alerting managers to insulation degradation or overheating risks before they escalate. This proactive approach complements AI-driven hazard prediction systems, creating layered safeguards for high-risk environments like chemical plants or semiconductor fabs.

For industries ready to future-proof their power infrastructure, www.nante.com offers solutions that harmonize rugged reliability with smart manufacturing’s dynamic needs. Explore how cutting-edge industrial socket boxes can energize your digital transformation journey.